What is Put to Light?

- Share

- Issue Time

- Mar 28,2024

Summary

One method gaining traction in warehouses worldwide is "Put to Light". This innovative system optimizes the picking and sorting processes, enhancing productivity and reducing errors.

In the realm of logistics and order fulfillment, efficiency is paramount. One method gaining traction in warehouses worldwide is 'Put to Light'. This innovative system optimizes the picking and sorting processes, enhancing productivity and reducing errors. Let's delve into what Put to Light entails and how it revolutionizes warehouse operations.

What is Put to Light?

Put to Light is a picking and sorting method where items are directed to specific locations using light indicators. It's a variation of the more widely known pick-to-light system. In Put to Light, items are brought to a central location and then distributed to individual bins or orders using light signals. These lights guide warehouse workers in placing the items accurately, ensuring that each order is correctly fulfilled.

How Does Put to Light Work?

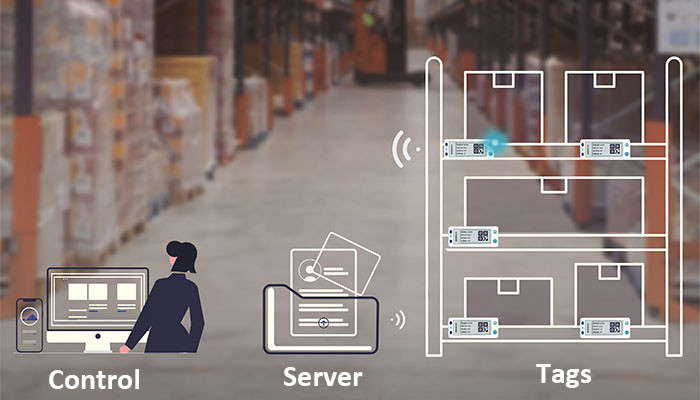

The Put to Light system typically involves several components:

Central Station: At the heart of the system is a central station equipped with light displays and controls. This station communicates with the warehouse management system (WMS) and receives information about incoming orders and items to be distributed.

Bins or Order Containers: These are the destinations for the items. Each bin corresponds to a specific order or location in the warehouse.

Put to Light Labels: Positioned above each bin, these lights illuminate to indicate where each item should be placed. The lights are controlled by the central station and guide workers in real-time.

Barcode or RFID Scanning: To ensure accuracy, items may be scanned upon arrival at the central station. This allows the system to match items with the correct orders and determine their destinations.

Workflow Integration: Put to Light systems are integrated with the overall workflow of the warehouse, seamlessly coordinating with other processes such as picking, packing, and shipping.

Benefits of Put to Light

Implementing Put to Light offers several advantages:

Increased Efficiency: By guiding workers to the exact location for item placement, Put to Light reduces the time spent searching for bins or orders, leading to faster fulfillment times.

Error Reduction: The visual cues provided by the light indicators help minimize picking errors, improving order accuracy and customer satisfaction.

Scalability: Put to Light systems can be easily scaled to accommodate growing inventory and order volumes, making them suitable for both small and large warehouses.

Real-time Monitoring: Managers can monitor the progress of order fulfillment in real-time, allowing for better resource allocation and performance optimization.

Flexibility: Put to Light systems can adapt to different warehouse layouts and workflows, offering flexibility to meet changing business needs.

In the fast-paced world of logistics, efficiency and accuracy are essential. Put to light systems address these needs by streamlining the order fulfillment process and enhancing productivity. With its intuitive design and tangible benefits, put to light is poised to continue transforming warehouse operations, driving greater efficiency and customer satisfaction.